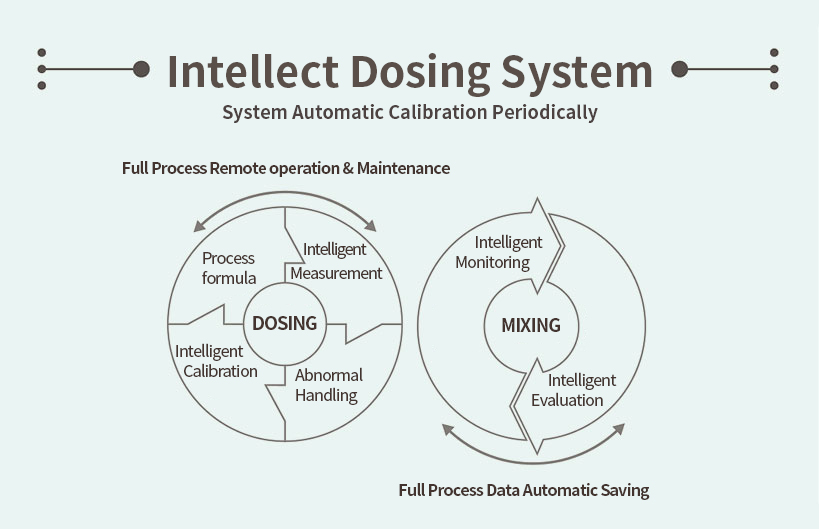

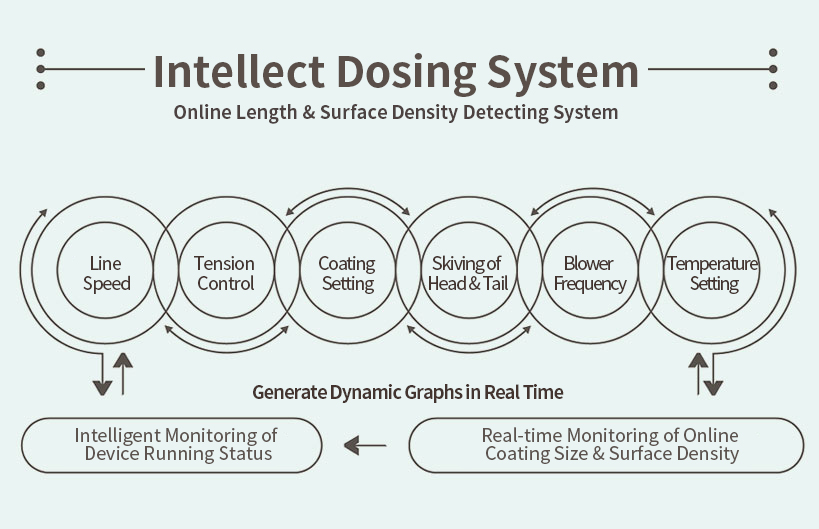

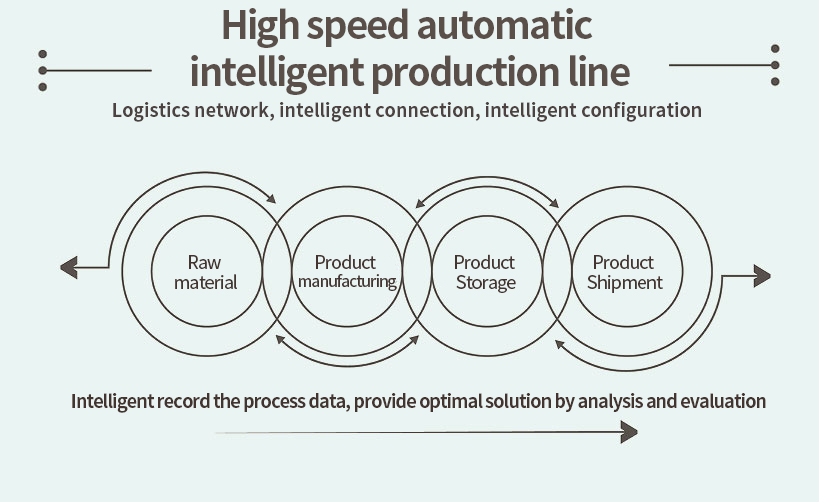

The assembling process and charge/discharge process are integrated into a whole high-speed, automatic and intelligent production line. Using network technology to connect production equipment and computer system, realizing information intelligent interaction, integrate people, machine, material, laws and principles, environment, supply chain and management. Intelligently record the process data, and provide optimal solution by analysis and evaluation, from raw material to product manufacturing, storage, shipping.

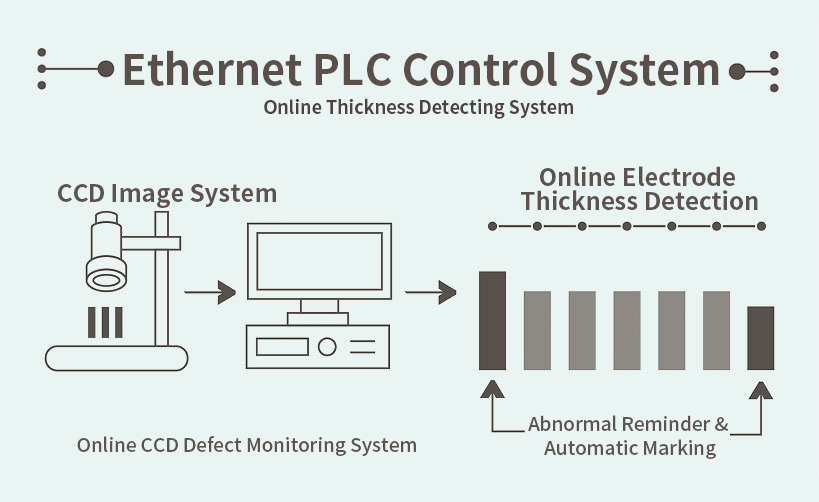

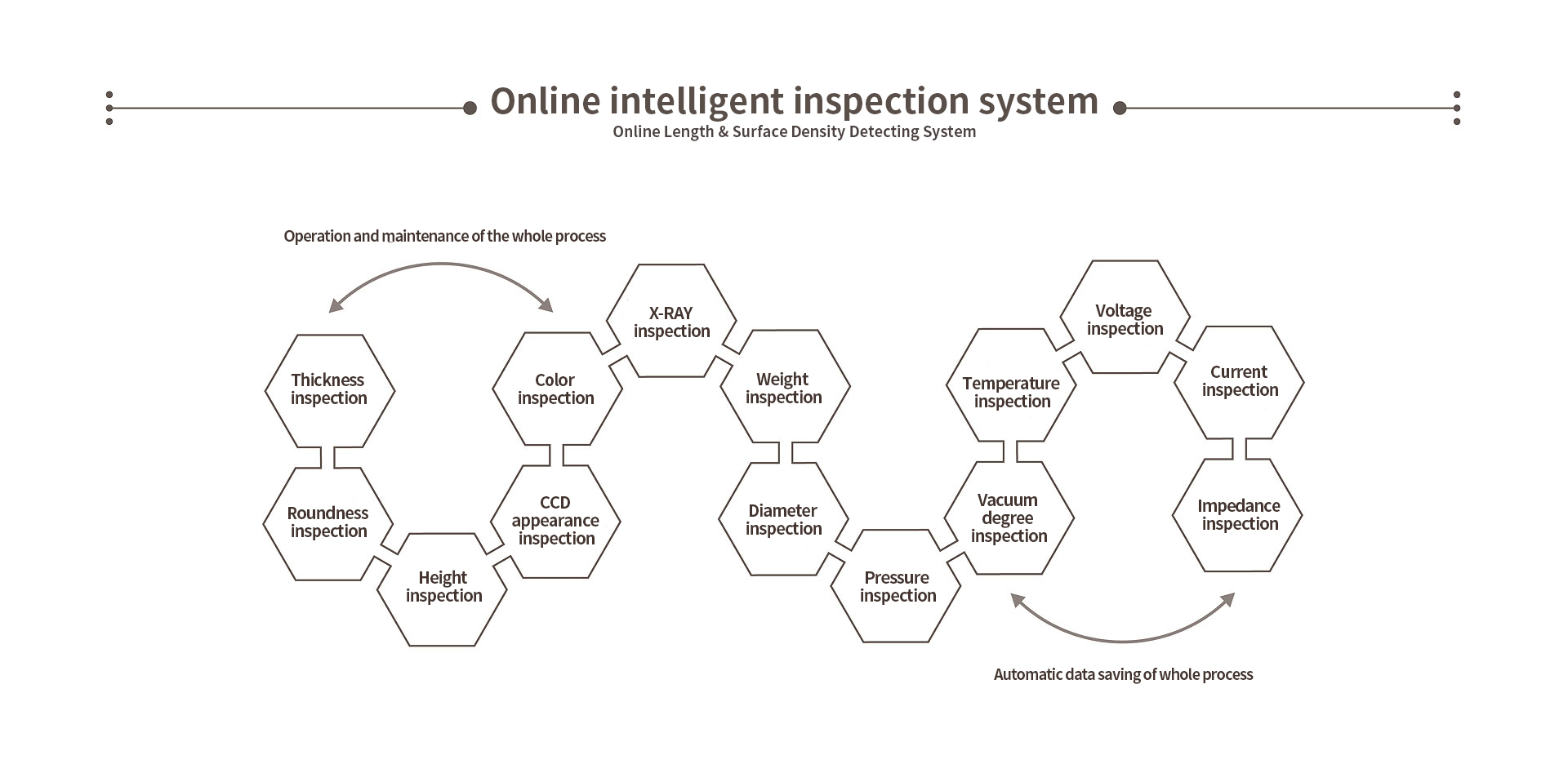

The processes are connected to each other by intelligent logistic network. Each process is equipped with online intelligent inspection system to record and save the process data (including thickness, roundness, height, status, CCD appearance, color, x-ray, weight, diameter, pressure, vacuum rate, temperature, voltage, current, impedance). The system can intelligently identify and automatically handle the abnormal. Adopting AS/RS system, the online product storage is able to maximize workshop floor area ratio, increase productivity and avoid error operation, connected to the computer system effectively to share the information and intelligently allocate.

The system is able to intelligently analysis product quality and equipment status according to the data, and intelligently asses early warning of life control of key components, also able to remote control and maintenance.